Back أكريلونتريل بوتاديين ستايرين Arabic آکریلونیتریل بوتادین استایرن AZB АБС-пластык Byelorussian Акрилонитрил-бутадиен-стирен Bulgarian Acrilonitril butadiè estirè Catalan Akrylonitrilbutadienstyren Czech Akrylonitril-butadien-styren Danish Acrylnitril-Butadien-Styrol-Copolymer German Acrilonitrilo butadieno estireno Spanish Akrilonitrilo-butadieno-estireno Basque

Monomers in ABS polymer

| |

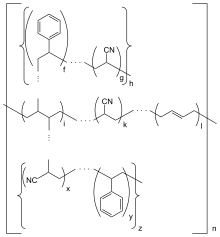

A subset of common crosslinking motifs in ABS

| |

ABS polymer grains

| |

| Identifiers | |

|---|---|

| ChemSpider |

|

| ECHA InfoCard | 100.127.708 |

PubChem CID

|

|

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C8H8·C4H6·C3H3N)n | |

| Density | 1.060–1.080 g/cm3[1] |

| Insoluble in water | |

| Related compounds | |

Related compounds

|

Acrylonitrile, butadiene and styrene (monomers) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

| Acrylonitrile butadiene styrene | |

|---|---|

| Physical properties | |

| Density (ρ) | 0.9–1.53 g/cm3; median, 1.07 g/cm3 |

| Flammability | 1.00 |

| Thermal properties | |

| Thermal conductivity (k) | 0.1 W/(m·K) |

| Linear thermal expansion coefficient (α) | 12×10−5 K−1 |

| Chemical resistance | |

| Acids—concentrated | Good |

| Acids—dilute | Excellent |

| Alcohols | Poor |

| Aldehydes | Poor |

| Alkalis | Excellent |

| Aromatic hydrocarbons | Poor |

| Esters | Poor |

| Halogenated hydrocarbons | Poor |

| Ketones | Poor |

| [2][3] | |

Acrylonitrile butadiene styrene (ABS) (chemical formula (C8H8)x·(C4H6)y·(C3H3N)z ) is a common thermoplastic polymer. Its glass transition temperature is approximately 105 °C (221 °F).[4] ABS is amorphous and therefore has no true melting point.

ABS is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15% to 35% acrylonitrile, 5% to 30% butadiene and 40% to 60% styrene. The result is a long chain of polybutadiene crisscrossed with shorter chains of poly(styrene-co-acrylonitrile). The nitrile groups from neighboring chains, being polar, attract each other and bind the chains together, making ABS stronger than pure polystyrene. The acrylonitrile also contributes chemical resistance, fatigue resistance, hardness, and rigidity, while increasing the heat deflection temperature. The styrene gives the plastic a shiny, impervious surface, as well as hardness, rigidity, and improved processing ease. The polybutadiene, a rubbery substance, provides toughness and ductility at low temperatures, at the cost of heat resistance and rigidity.[3] For the majority of applications, ABS can be used between −20 and 80 °C (−4 and 176 °F), as its mechanical properties vary with temperature.[5] The properties are created by rubber toughening, where fine particles of elastomer are distributed throughout the rigid matrix.

- ^ "Matbase". Archived from the original on 17 June 2014. Retrieved 3 July 2014.

- ^ "Chemical & Environmental Resistance of Thermoplastics". rtpcompany.com. 10 September 2013.

- ^ a b Peters, Edward N., "Plastics: Thermoplastics, Thermosets, and Elastomers", Handbook of Materials Selection, New York: John Wiley & Sons, Inc., pp. 363–365

- ^ "Glass Transition of ABS in 3D Printing" (PDF).

- ^ Plastic Properties of Acrylonitrile Butadiene Styrene (ABS). Archived May 15, 2010, at the Wayback Machine. Small table of ABS properties towards the bottom. Retrieved 7 May 2010.

© MMXXIII Rich X Search. We shall prevail. All rights reserved. Rich X Search