Back مفاعل الملح المنصهر Arabic Reactor de sal fosa Catalan Reaktor založený na roztavených solích Czech Saltreaktor Danish Flüssigsalzreaktor German Fluidsala reaktoro Esperanto Reactor de sal fundida Spanish رآکتور نمک گداخته Persian Sulasuolareaktori Finnish Réacteur nucléaire à sels fondus French

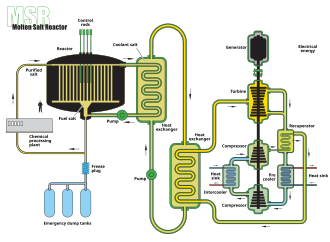

A molten-salt reactor (MSR) is a class of nuclear fission reactor in which the primary nuclear reactor coolant and/or the fuel is a mixture of molten salt with a fissile material.

Two research MSRs operated in the United States in the mid-20th century. The 1950s Aircraft Reactor Experiment (ARE) was primarily motivated by the technology's compact size, while the 1960s Molten-Salt Reactor Experiment (MSRE) aimed to demonstrate a nuclear power plant using a thorium fuel cycle in a breeder reactor.

Increased research into Generation IV reactor designs renewed interest in the 21st century with multiple nations starting projects. As of May 2023, China had not announced the ignition of its TMSR-LF1 thorium unit following its scheduled date of February 2023.[1][2]

MSRs eliminate the nuclear meltdown scenario present in water-cooled reactors because the fuel mixture is kept in a molten state. The fuel mixture is designed to drain without pumping from the core to a containment vessel in emergency scenarios, where the fuel solidifies, quenching the reaction. In addition, hydrogen evolution does not occur. This eliminates the risk of hydrogen explosions (as in the Fukushima nuclear disaster).[2] They operate at or close to atmospheric pressure, rather than the 75–150 times atmospheric pressure of a typical light-water reactor (LWR). This reduces the need and cost for reactor pressure vessels. The gaseous fission products (Xe and Kr) have little solubility in the fuel salt,[a] and can be safely captured as they bubble out of the fuel,[b] rather than increasing the pressure inside the fuel tubes, as happens in conventional reactors. MSRs can be refueled while operating (essentially online-nuclear reprocessing) while conventional reactors shut down for refueling (notable exceptions include pressure tube heavy water reactors like the CANDU or the Atucha-class PHWRs, and British-built gas-cooled reactors such as Magnox, AGR). MSR operating temperatures are around 700 °C (1,292 °F), significantly higher than traditional LWRs at around 300 °C (572 °F). This increases electricity-generation efficiency and process-heat opportunities.

Relevant design challenges include the corrosivity of hot salts and the changing chemical composition of the salt as it is transmuted by the neutron flux.

- ^ Cite error: The named reference

msrs-wnawas invoked but never defined (see the help page). - ^ a b Smriti Mallapaty (9 September 2021). "China prepares to test thorium-fuelled nuclear reactor". Nature. 597 (7876): 311–312. Bibcode:2021Natur.597..311M. doi:10.1038/d41586-021-02459-w. PMID 34504330. S2CID 237471852. Retrieved 10 September 2021.

Molten-salt reactors are considered to be relatively safe because the fuel is already dissolved in liquid and they operate at lower pressures than do conventional nuclear reactors, which reduces the risk of explosive meltdowns.

- ^ Forsberg, Charles W. (26 September 2002). "Molten Salt Reactors (MSRs)" (PDF). File: GenIV.MSR.ANES.2002.rev1

- ^ "Safety – ThorCon". ThorCon.com. 2022. Retrieved 29 May 2023.

- ^ "Status Report to IAEA" (PDF). IAEA Advanced Reactor Information System. 22 June 2020. §2.2 Reactor core and fuel.

The He, Xe, and Kr gas mixture then flows from the Can through two hold-up tanks and a charcoal delay line in the secondary heat exchanger cell. The gas flow continues to a cryogenic gas processing system to separate the gasses, storing stable Xe and radioactive Kr-85 in gas bottles and returning He for reuse as a sweep gas

Cite error: There are <ref group=lower-alpha> tags or {{efn}} templates on this page, but the references will not show without a {{reflist|group=lower-alpha}} template or {{notelist}} template (see the help page).

© MMXXIII Rich X Search. We shall prevail. All rights reserved. Rich X Search