Back O-Ring ALS حلقة مستديرة Arabic Junta tòrica Catalan O-Ring German Tororingeto Esperanto Junta tórica Spanish Juntura torikoa Basque اورینگ Persian O-rengas Finnish Joint torique French

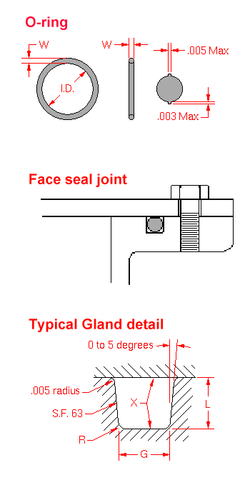

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, forming a seal at the interface.

The O-ring may be used in static applications or in dynamic applications where there is relative motion between the parts and the O-ring. Dynamic examples include rotating pump shafts and hydraulic cylinder pistons. Static applications of O-rings may include fluid or gas sealing applications in which: (1) the O-ring is compressed resulting in zero clearance, (2) the O-ring material is vulcanized solid such that it is impermeable to the fluid or gas, and (3) the O-ring material is resistant to degradation by the fluid or gas.[1] The wide range of potential liquids and gases that need to be sealed has necessitated the development of a wide range of O-ring materials.[2]

O-rings are one of the most common seals used in machine design because they are inexpensive, easy to make, reliable and have simple mounting requirements. They have been tested to seal up to 5,000 psi (34 MPa) of pressure.[3] The maximum recommended pressure of an O-ring seal depends on the seal hardness, material, cross-sectional diameter, and radial clearance.[4]

- ^ Whitlock, Jerry (2004). "The Seal Man's O-Ring Handbook" (PDF). EPM, Inc. - The Seal Man. Archived from the original (PDF) on 2019-08-10. Retrieved 2018-12-08.

- ^ "GFS O-Rings". Gallagher Seals. Retrieved 4 August 2021.

- ^ Pearl, D.R. (January 1947). O-Ring Seals in the Design of Hydraulic Mechanisms. S.A.E. Annual Meeting. Hamilton Standard Prop. Div. of United Aircraft Corp.

- ^ "Frequently Asked O-ring Technical Questions". Parker O-Ring & Engineered Seals Division. Retrieved December 7, 2018.

© MMXXIII Rich X Search. We shall prevail. All rights reserved. Rich X Search