Back Màquina d'inserció de components Catalan Bestückungsautomat German دستگاه برداشت و گذاشت Persian チップマウンター Japanese Машина Pick and Place Ukrainian

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these template messages)

|

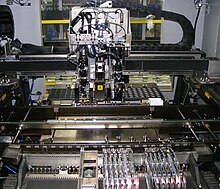

Surface-mount technology (SMT) component placement systems, commonly called pick-and-place machines or P&Ps, are robotic machines which are used to place surface-mount devices (SMDs) onto a printed circuit board (PCB). They are used for high speed, high precision placing of a broad range of electronic components, for example capacitors, resistors, integrated circuits onto the PCBs which are in turn used in computers, consumer electronics as well as industrial, medical, automotive, military and telecommunications equipment. Similar equipment exists for through-hole components.[1][2] This type of equipment is sometimes used to package microchips using the flip chip method.

- ^ "PCB Assembly Example". Fuji. Archived from the original on April 1, 2018.

- ^ "SMT-JUKI, pioneer of "Multi Task Platform JM-20"". www.juki.co.jp.

© MMXXIII Rich X Search. We shall prevail. All rights reserved. Rich X Search