Back Spinning mule Catalan Spinning mule Czech Spinning mule Danish Spinning Mule German Ŝpinilmulo Esperanto Mula de hilar Spanish Mule-jenny French Miúil (gléas) Irish Spunavél Icelandic ミュール紡績機 Japanese

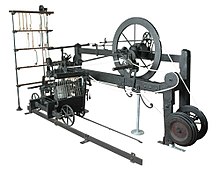

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be 150 feet (46 m) long, and would move forward and back a distance of 5 feet (1.5 m) four times a minute.[1]

It was invented between 1775 and 1779 by Samuel Crompton. The self-acting (automatic) mule was patented by Richard Roberts in 1825. At its peak, there were 50,000,000 mule spindles in Lancashire alone. Modern versions are still in production and are used to spin woollen yarns from noble fibres such as cashmere, ultra-fine merino and alpaca for the knitted textile market. [2][3]

The spinning mule spins textile fibres into yarn by an intermittent process.[4] In the draw stroke, the roving is pulled through rollers and twisted; on the return it is wrapped onto the spindle. Its rival, the throstle frame or ring frame, uses a continuous process, where the roving is drawn, twisted and wrapped in one action. The mule was the most common spinning machine from 1790 until about 1900 and was still used for fine yarns until the early 1980s. In 1890, a typical cotton mill would have over 60 mules, each with 1,320 spindles,[5] which would operate four times a minute for 56 hours a week.

- ^ Catling 1986, p. 11

- ^ Cite error: The named reference

Bigagliwas invoked but never defined (see the help page). - ^ Cite error: The named reference

Cormatexwas invoked but never defined (see the help page). - ^ Marsden 1884, p. 109

- ^ Nasmith 1895, p. 109

© MMXXIII Rich X Search. We shall prevail. All rights reserved. Rich X Search